Industrial investment casting and investment casting process

Welcome to LLOYD Industrial Parts, your expert for precision casting based in the traditional Hanseatic city of Bremen.

With years of experience in the investment casting process, we offer you the highest quality for complex and individually manufactured investment castings made of stainless steel and aluminum using the lost wax process.

What we do.

Your expert for investment casting.

In the dynamic world of mechanical engineering, quality, precision and efficiency are of crucial importance. Our team of experts, deeply rooted in old Hanseatic traditions, fulfills the industrial requirements of the science of investment casting and investment casting processes with years of expertise.

In the heart of Northern Germany, we offer you the highest quality for individually manufactured investment castings (small and large series) as investment cast stainless steel and investment cast aluminum according to the lost wax process and comprehensive customer service, which, in addition to high technical expertise, does not neglect personal contact.

Contact us for an individual offer or a free consultation on investment casting.

Our quality promise.

LLOYD Industrial Parts: Innovation und Qualität aus einem Guss.

Thanks to years of expertise in investment casting, we are able to produce complex and precise parts for you.

Compliance with the highest quality standards is a matter of course for us. Our integrated quality management system guarantees that every product that leaves our warehouse complies with our strict quality controls.

The use of state-of-the-art technology and efficient production processes allows us to keep the costs of components and tools low without compromising on quality.

- Years of expertise in investment casting

- Competitive prices

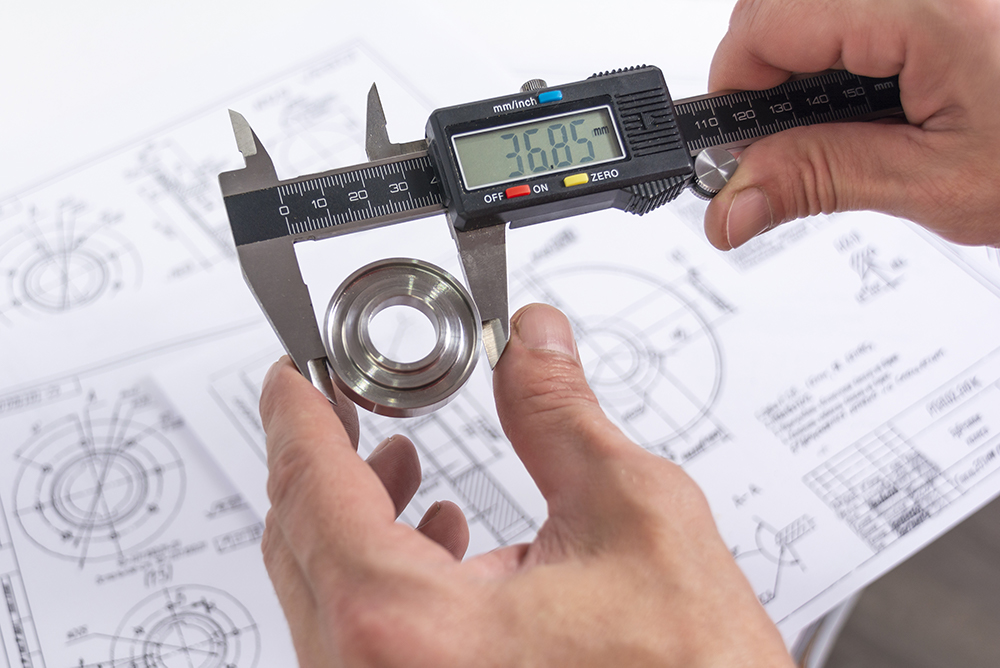

- High dimensional accuracy

- Cost efficiency

- High quality standards

- Production of small and large series

At LLOYD Industrial Parts, we attach great importance to individual solutions and personal advice. Quality, performance and customer proximity are our top priorities. In keeping with Hanseatic tradition.

One of the remarkable properties of investment casting is its high dimensional accuracy.

Compared to other casting processes, the deviations in the investment casting process are minimal.

Tolerances of a few tenths of a millimeter are often achieved, which enables enormous precision, especially with highly complex components.

They show fewer deviations and correspond exactly to the specific requirements and tolerances required for their application.

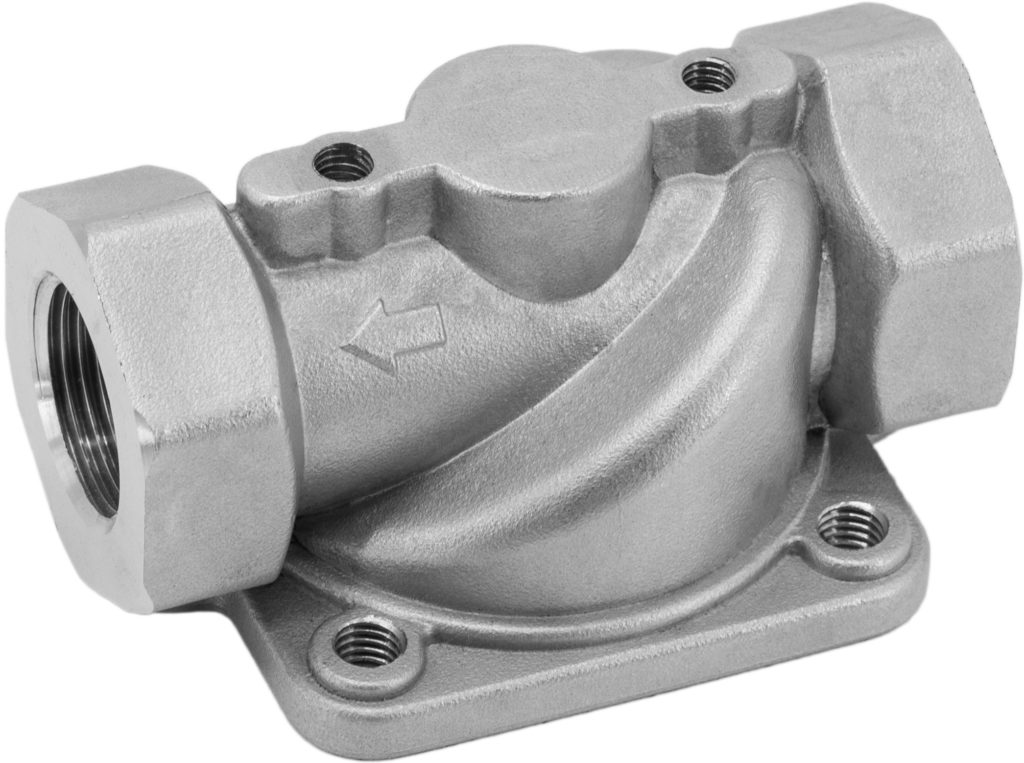

Another major advantage of investment casting is the ability to create very complex and difficult shapes and structures that would not be feasible with other casting techniques

.

Investment casting technology is compatible with a wide range of materials, from unalloyed steel to stainless steel alloys, aluminum and bronze.

Another characteristic is the high surface quality. Components produced using investment casting generally have a smooth and clean surface. This often reduces the need for subsequent machining or surface finishing.

Thanks to our expertise in investment casting and surface treatment, we guarantee the high surface quality of our products. This makes them not only extremely functional, but also visually appealing.

Despite the high quality and precision, investment casting can in many cases be more cost effective than other techniques. The ability to produce a near net shape can significantly reduce the need for expensive reworking.

Compliance with the highest quality standards in investment casting is a matter of course for us.

Our integrated quality management system guarantees that every cast product that leaves our warehouse complies with our strict quality controls.

Our efficient production process and the strategic positioning of our production facilities enable us to offer high-quality products at competitive prices.

The use of state-of-the-art technology and efficient production processes allows us to keep the costs of components and tools low without compromising on quality.

Whether you need a few special parts (small series) or large production quantities (large series), we adapt to your requirements and ensure that we meet your expectations in terms of quality, cost and delivery time.

Our commitment to excellent customer service is a central pillar of our corporate philosophy.

Our team of experts is at your side from the initial contact to product delivery, ensuring that your specific requirements are met efficiently and to your complete satisfaction.

Our innovative design and engineering team specializes in translating your ideas into precise technical drawings and designs (CAD).

We work closely with you to understand your requirements and develop the best possible solutions to meet your specific needs.

We check whether your components are designed for investment casting, redefine the required tolerances and determine the material allowances for mechanical processing.

We revise your drawings and adapt the standards and specifications to the requirements for quality castings.

Your advantages.

Investment casting: an industry standard.

Investment casting is a highly developed technique that is characterized by its ability to produce precise and detailed components.

This casting process is used in numerous industries: From the automotive industry to mechanical engineering and modern medical technology.

The advantages are obvious.

Investment casting helps to fulfill even difficult and precise requirements that other traditional processes often cannot achieve.

While conventional casting, for example, often requires extensive post-processing, investment casting often enables a final form that is almost close to production, which reduces or partially eliminates the need for further processing steps.

The special properties of investment casting, such as high dimensional accuracy, surface quality, the ability to produce complex geometries and compatibility with a wide range of materials, have made it the preferred process for manufacturing high-precision components.

In addition, investment casting enables the production of components with considerable material savings and therefore cost efficiency.

All these advantages make investment casting an indispensable part of modern production technology.

Whether you need a few special parts (small series) or large production quantities (large series), we adapt to your requirements and ensure that we meet your expectations in terms of quality, cost and delivery time.

Are you interested?

Contact us today for a free quote or individual consultation.

Our process.

The steps of the investment casting process -

from prototype to perfection.

The investment casting process at LLOYD Industrial Parts is a high-precision manufacturing process that is divided into the following steps:

1. contact

The first thing you do is contact us to give us an insight into your specific needs and requirements for your component. During this phase, our experts will consult you on the feasibility of your component, the materials to be used and all other relevant factors. We are also happy to help with the design and drawing.

2. production of the tools

In the next phase, the molds are produced. These are used to create an exact wax model of your component. They are usually made from aluminum and tailored to the customer's specific requirements.

3. wax model build-up

In the next step, the injection molding tool is used to create an accurate wax model of your component. The wax models represent the end product in its final form and serve as a master for the subsequent process step.

4. ceramic build-up & lost wax technique

The wax model is now embedded in a ceramic shell. To do this, the wax model is doused several times with ceramic slip and sprinkled with fine ceramic sand. Once the shell has dried and hardened sufficiently, the wax model is melted out, leaving behind a high-precision, hollow ceramic mold.

5. casting of the melt

Now the actual investment casting takes place. The previously heated ceramic mold is poured with the molten metal. After cooling, the ceramic shell is removed and the raw casting becomes visible.

6 Finishing and assembly

This step includes the mechanical post-processing of the cast part to remove casting burrs and skins. Depending on requirements, heat or surface treatment can be carried out before the components are sent on for assembly

7. final quality control

We carry out strict quality control to ensure that all components produced meet the requirements. We use the latest testing techniques to ensure the required quality standards.

8. shipping "free domicile"

We are proud to be able to offer our customers a "free delivery" service. This means fewer complications and time savings for you, as we take care of all the logistics from production to delivery to your premises.

FAQ

Questions and answers

Why is it called investment casting?

The term investment casting is derived from the fact that very fine, detailed and precise components can be produced using this process. It enables the production of workpieces with complicated shapes and high dimensional accuracy requirements.

Is there a minimum purchase quantity?

The minimum order quantity for investment casting depends heavily on the individual requirements and circumstances. In principle, however, investment casting is also suitable for the production of smaller quantities. However, you should consult your contact person on an individual basis.

Are the final components ready for installation?

As a rule, investment castings have to be reworked after the actual casting process. This includes deburring, machining of defined areas and, if necessary, heat treatment and surface treatment or painting.

Which alloys are used?

A wide range of materials can be processed using the investment casting process. Various steels and stainless steels, aluminum alloys, brass alloys, copper alloys and various special alloys are frequently used.

What is investment casting used for?

Investment casting is primarily used in the production of components and parts with high contour accuracy and complex shapes, where conventional casting processes reach their limits. Areas of application include mechanical engineering, the automotive industry, the aerospace industry, medical technology and jewelry manufacturing.

How are castings produced during investment casting?

In the investment casting process, a model of the desired component is first created from wax or plastic. This model serves as the starting point for creating a casting mold made of heat-resistant material, usually ceramic. The model is then melted out (lost wax process) and the resulting hollow mold is poured with the liquid material. After cooling and hardening, the mold is broken open and the casting is removed.

What casting methods are there?

There are a variety of casting processes. In addition to investment casting, other common methods include sand casting, die casting, gravity die casting and centrifugal casting. Each process has its own special advantages and is used depending on the requirements of the workpiece.

What molds are available?

There are different types of molds that are used depending on the casting process selected. These include, for example, models made of wood or metal for the sand casting process, metal molds for the die casting process or wax models for the investment casting process (lost wax process).

How does the lost wax process work?

In the lost wax process, a wax model of the part to be produced is embedded in a refractory ceramic material. Once the mold has hardened, the wax is heated and melted to create a perfect, hollow replica of the component. The metal is poured into this mold, which takes on the shape of the original model once it has solidified in the mold.

What is the difference between investment casting and gray cast iron?

Gray cast iron is cast iron with lamellar graphite inclusions. It is easy to pour

and is characterized by its high damping of vibrations. Investment casting, on the other hand, is

a process and not a material. A variety of

materials, including gray cast iron, can be used in the investment casting technique. The difference therefore lies in the

different areas of application and the specific properties of the materials

or processes.

CONTACT.

Our experts are ready to answer your questions about the production of investment castings, discuss technical details or prepare a quote for your next project

We invite you to take the first step and contact us – by phone, e-mail or via our online contact form on our website.

According to the North German motto: Just get in touch.

E-Mail: info@lloyd-parts.de

Phone: +49 421 835 265 20

Service offer

Further services

In addition to our core competence in investment casting, we offer a wide range of additional services that can optimize and simplify your production processes. Expand your range of services with our all-round carefree packages.

Metal Injection Molding (MIM)

With the MIM process, we offer you an advanced technology for the production of precise and complex metal parts of the highest quality. This method enables the processing of a wide range of metallic materials with almost unlimited design possibilities.

CNC production

Thanks to state-of-the-art CNC-controlled machines, we guarantee precise and efficient machining of your components.

Various milling and turning processes enable us to realize complex shapes and contours according to your specifications.

Component assembly

Our range of services also includes component assembly. We take care of the assembly and adjustment of individual parts into functional assemblies so that you can concentrate on your core competencies. We install efficiently and to a high standard using the latest technologies and precisely according to your requirements.